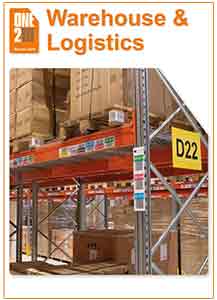

Why use colour-coded rack labels?

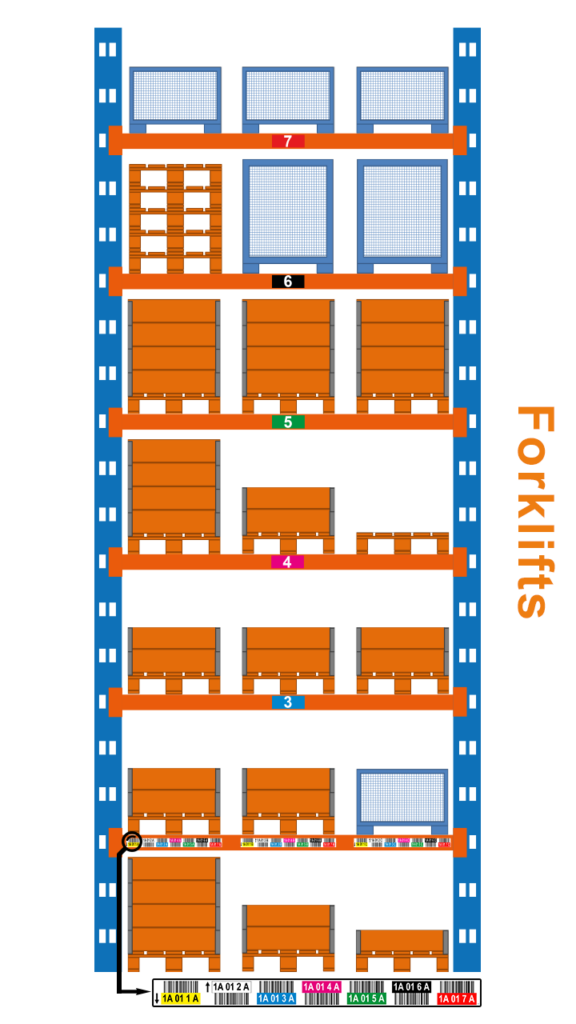

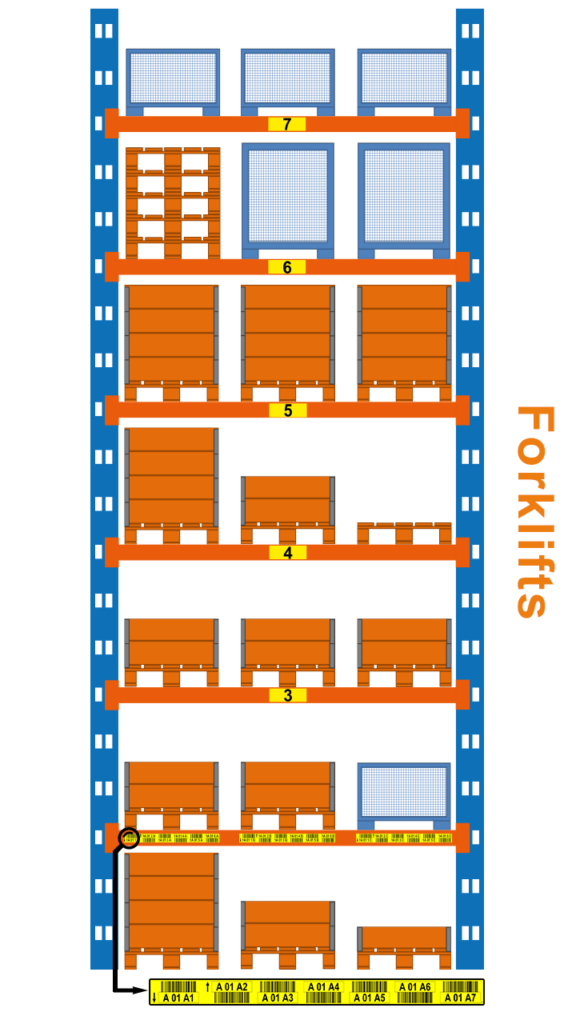

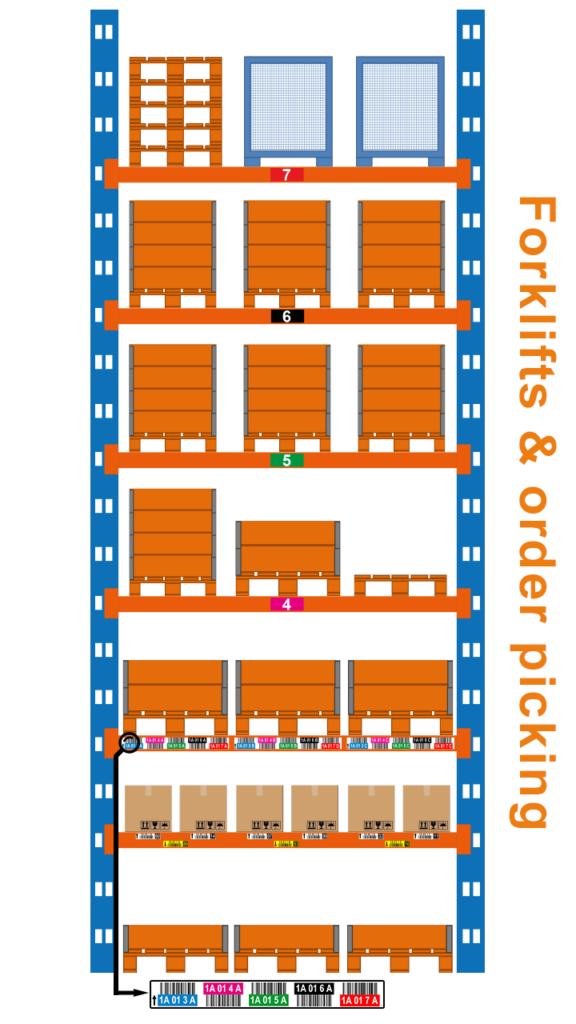

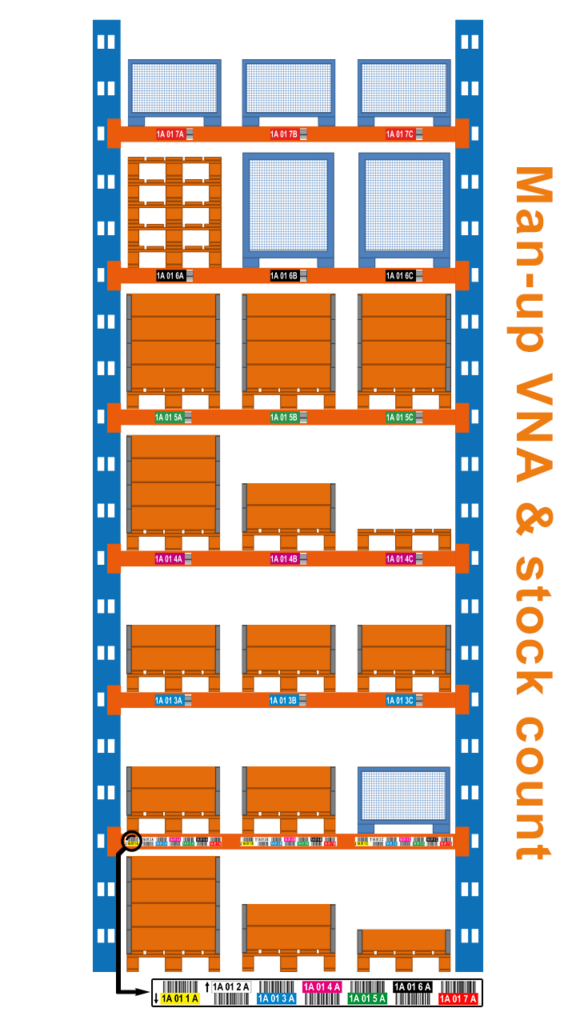

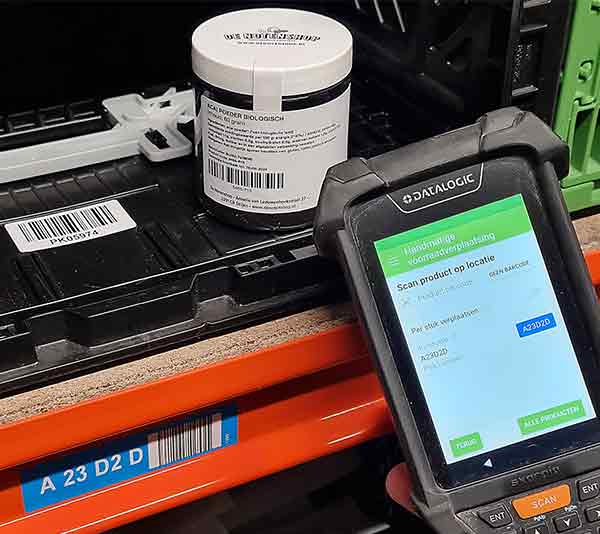

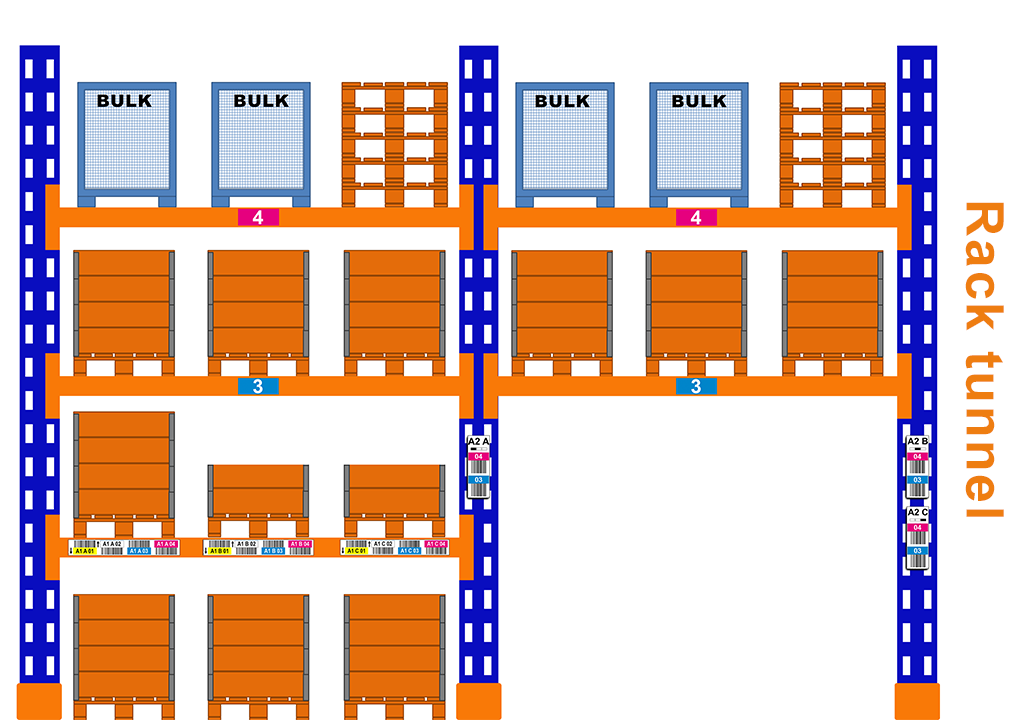

Rack labels that are both legible and easily recognisable are essential to the day-to-day operations of any warehouse. After all, you want your goods to be stored in the right place and delivered to the right customers. This process requires an efficient warehouse management system with matching software and well-designed barcode labels. If you are used to working with standardised yellow or white labels, colour-coded rack labels with corresponding colours on the beams of each pallet rack level offer several advantages to your warehouse operations.